Our plant is spread over a vast area of 4,50,000 square feet with annual production capacity of 4.8 million insulating bricks and 2400MT castables and motars. Excellence emanates from our well equipped work area where strict adherence is maintained to in- production procedures from raw material procurement to packaging. Our plant is equipped with latest production facilities ranging from processing of raw materials to finished product which includes the conventional bricks making facility as well as separate section for high purity bricks confirming to ASTM C155- Gr. 20,23,26,28 & ISO- 2245 standards.

We also undertake manufacturing of complex and large sized shapes through Pre-cast & Pre-fired route. Our plant facility includes Grinding, state of the art Batching & Mixing unit, vast section of extruders, state of the art brick cutting machine for higher dimensional accuracy, sea worthy water proof packaging & palletization facility, latest Tunnel Kilns & Oil fired conventional Round Kilns. Our kilns have been specially designed and modified based on the guidance of our R&D team and the experience that we have gained as veteran players in this industry. Different products and qualities are fired in different furnaces and conditions. We are the pioneers in India to successfully introduce and execute oil firing in conventional round kilns.

Quality Assurance

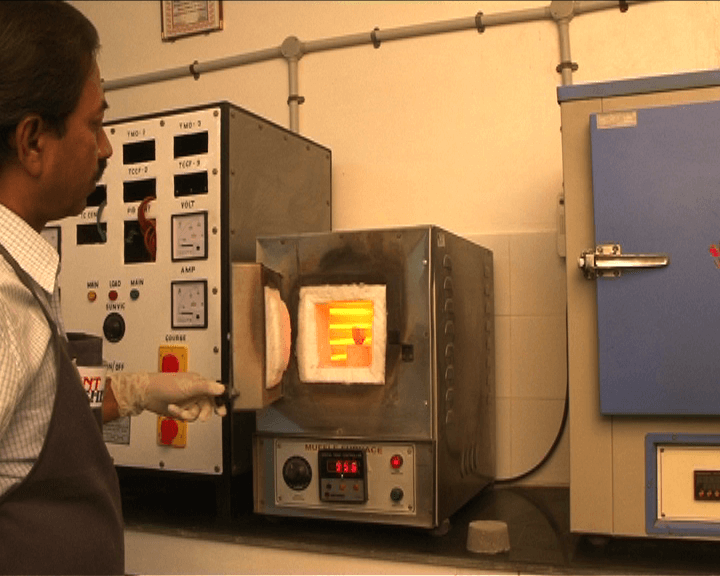

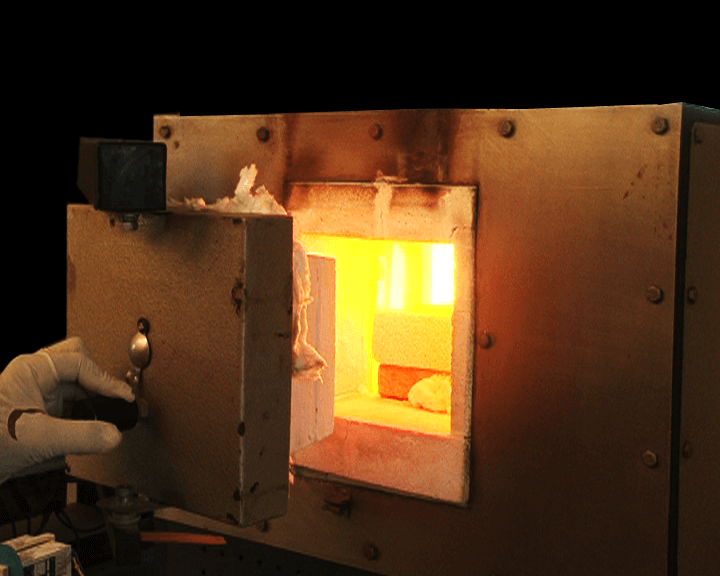

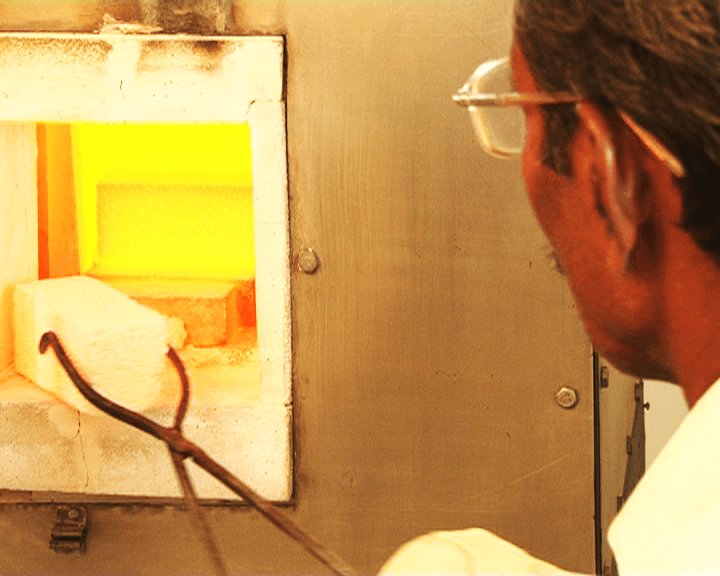

Being a quality oriented organization, we are dedicated to provide our customers with the best quality products. For this, we have adhered many quality regulatory measures. These measures include the setting up of a quality control department, which performs various tests to verify the quality of our products. These quality tests are performed under the strict supervision of our highly technical professionals to ensure the quality of our products. Right from the selection of raw materials till the final supplying of our products, we leave no stone unturned in assuring the quality of our products at every stage.

Modern R & D laboratory

We have an inhouse ultra modern laboratory equipped with all latest facilities to evaluate physical and chemical properties of our products as per ASTM, BIS, ISO test standards which includes.

- Thermal conductivity

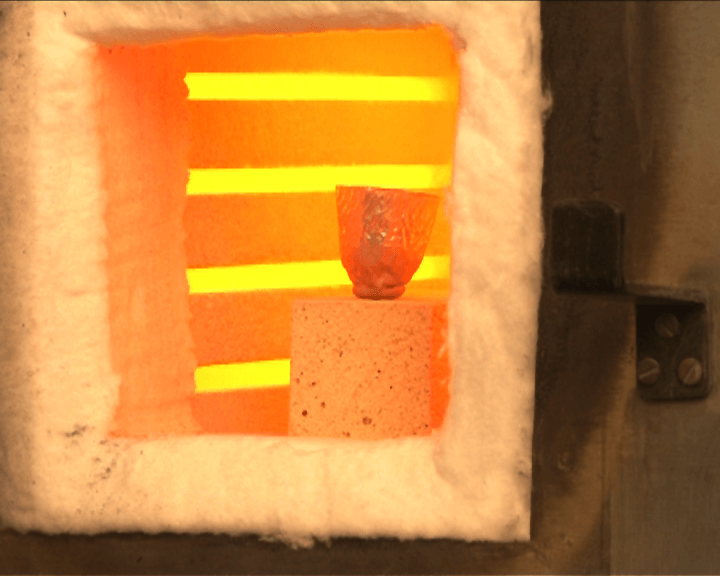

- Linear Re-Heat Shrinkage

- Refractoriness

- Refractoriness under load

- Cold Crushing Strength

- Modulas Of Rupture

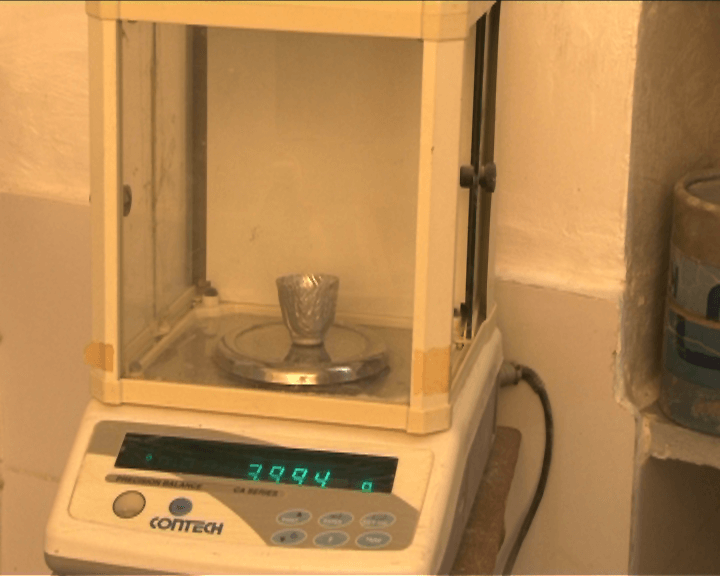

- Density

- Apparent Porosity

- Reverseable Thermal Expansion

- Sieve Analysis

- Chemical Compositions

Our facilities & products have also been approved by major technology designers and engineering consultants like

- Engineers India Ltd.

- Mecon Ltd.

- M. N. Dastur & Co.

- Centre for Engg. & Technology.